Understanding Supply Chain Fundamentals

Supply chain management (SCM) is an intricate network of processes that ensures the seamless movement of goods, services, and information from the point of origin to the end consumer. At its core, the definition of supply chain encompasses the interconnected activities involved in the production and delivery of products, spanning multiple entities such as suppliers, manufacturers, distributors, and retailers. Each player within this network performs a critical function, contributing to the overall efficiency and effectiveness of the supply chain.

The key components of supply chain management include sourcing, production, distribution, and logistics. Sourcing involves identifying and engaging suppliers who provide the necessary raw materials. Production refers to the transformation of these materials into finished products, while distribution encompasses the logistics of delivering these goods to various points of sale. Effective coordination among these elements is essential to minimize costs, improve customer satisfaction, and ensure timely delivery.

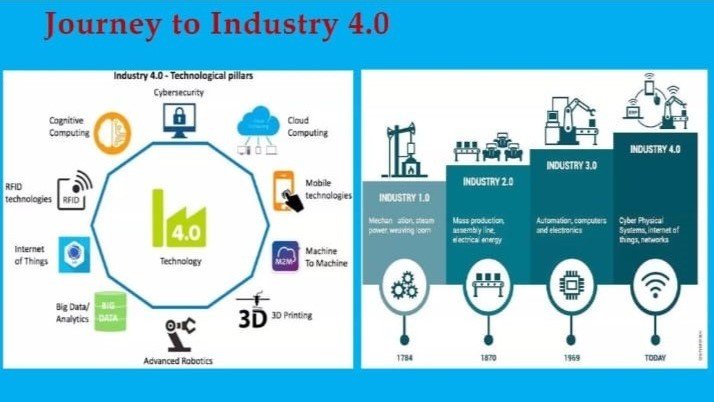

In today’s dynamic business landscape, the importance of effective supply chain strategies cannot be overstated. With globalization, companies are no longer limited to local suppliers and markets; they operate in a complex global ecosystem where the sourcing and distribution of goods can significantly impact overall competitiveness. Furthermore, technological advancements such as automation, artificial intelligence, and data analytics have revolutionized supply chain operations. These technologies empower businesses to manage inventory better, predict demand fluctuations, and enhance visibility throughout the supply chain.

Additionally, consumer behavior plays a pivotal role in shaping supply chain dynamics. As customers increasingly demand faster delivery times and more personalized services, companies must adapt their supply chain strategies accordingly. The ability to respond swiftly to changing consumer preferences is a key determinant of success in the modern marketplace. Thus, understanding supply chain fundamentals is essential for businesses aiming to navigate the complexities of SCM efficiently.

Challenges in Supply Chain Management

Effective supply chain management poses numerous challenges that organizations must navigate to remain competitive. One primary issue is demand variability, which can lead to misalignment between inventory levels and actual consumer needs. For instance, unexpected spikes in demand during holiday seasons can leave companies scrambling to fulfill orders, resulting in lost sales and customer dissatisfaction. To mitigate these risks, businesses often adopt advanced forecasting techniques to better predict demand patterns.

External factors also complicate supply chain operations significantly. Economic fluctuations can impact production costs and consumer purchasing power, creating a ripple effect throughout the supply chain. Natural disasters, such as hurricanes or earthquakes, can disrupt logistics and transportation networks, while geopolitical events may result in sudden trade policy changes or tariffs that complicate sourcing and distribution strategies.

Internally, organizations face challenges such as communication gaps among departments, which can lead to misinformation and delayed decision-making. For example, if the sales department is unaware of production delays, they may promise delivery times that the operations team cannot meet. Inadequate technology further exacerbates these issues; many companies still rely on outdated systems for tracking inventory and managing orders, reducing overall efficiency.

Another significant internal challenge is the lack of visibility across the supply chain. Without real-time data on inventory levels, shipments, and supplier performance, organizations struggle to react quickly to changing conditions. A real-world example includes the semiconductor shortage that affected various industries, showcasing how interconnected and vulnerable modern supply chains can be. As businesses grapple with these multifaceted challenges, finding innovative solutions becomes crucial for sustaining operational effectiveness and customer satisfaction.

Strategies for Optimizing Supply Chain Operations

Optimizing supply chain operations is crucial for organizations aiming to enhance efficiency and resilience. One effective strategy is the implementation of lean management principles. Lean management focuses on minimizing waste while maximizing value, ensuring that every activity in the supply chain adds value to the end customer. By identifying and eliminating non-value-added activities, organizations can improve their overall operational efficiency.

Another vital strategy is just-in-time (JIT) inventory management, which enables businesses to reduce inventory costs by receiving goods only as needed for production. This approach requires precise demand forecasting, which can be significantly enhanced through the utilization of advanced data analytics. By accurately predicting customer demand, organizations can adjust their inventory levels accordingly, reducing holding costs while ensuring product availability.

Incorporating automation into supply chain operations is also a critical optimization tactic. Automation can streamline processes, reduce human error, and free up personnel for more strategic tasks. Technologies such as robotics, conveyor systems, and automated inventory management systems can improve speed and accuracy in handling goods, leading to significant productivity gains.

The importance of technology in supply chain optimization cannot be overstated. Artificial Intelligence (AI) and machine learning enable organizations to analyze large datasets, uncover patterns, and make data-driven decisions. These technologies assist in optimizing routes for transportation, predicting equipment failures, and enhancing supply chain visibility, which ultimately leads to more informed decision-making.

Moreover, collaboration among stakeholders is essential in building a robust supply chain. Effective communication and partnerships with suppliers, manufacturers, and distributors facilitate a more resilient supply chain capable of adapting to disruptions. By fostering collaboration and forming strategic alliances, organizations can ensure a more integrated approach to supply chain management, enhancing overall performance and sustainability.

The Future of Supply Chain Management

The landscape of supply chain management is undergoing a significant transformation, driven by emerging trends and innovations that are reshaping operations globally. One of the foremost trends is the integration of sustainability practices into supply chain strategies. Companies are increasingly recognizing the need to adopt environmentally friendly practices that not only minimize their carbon footprint but also enhance their corporate reputation. Sustainable supply chains involve optimizing resource use, reducing waste, and collaborating with suppliers who prioritize eco-friendly practices, thus fostering a more responsible approach to business.

Another notable advancement is the adoption of blockchain technology, which is poised to revolutionize supply chain transparency and traceability. By providing a decentralized ledger that securely records transactions, blockchain enables real-time tracking of goods as they move through the supply chain. This innovation enhances accountability, improves trust among supply chain partners, and facilitates compliance with regulatory requirements. As organizations strive for greater visibility, blockchain systems become crucial in mitigating risks associated with fraud and product recalls.

The role of e-commerce continues to expand, dramatically influencing supply chain dynamics. With the shift towards online shopping, businesses must adapt their supply chains to meet the demands of rapid delivery and increased customer expectations. This shift emphasizes the need for agile and flexible logistics solutions, such as last-mile delivery options and technology-driven inventory management systems, to ensure that organizations can respond promptly to shifting market demands.

Furthermore, digital transformation is at the forefront of supply chain innovation, driving automation and data analytics implementation. Companies that embrace digital tools can improve decision-making, forecast demand more accurately, and streamline operations. The ability to harness data effectively allows organizations to identify trends, optimize processes, and enhance overall efficiency.

In conclusion, as supply chain management evolves, businesses must prioritize adaptability and agility. Future-proofing supply chains against potential disruptions requires a keen understanding of emerging trends and technologies that can enhance resilience and performance. By embracing these innovations and strategies, organizations can position themselves for success in an increasingly complex marketplace.