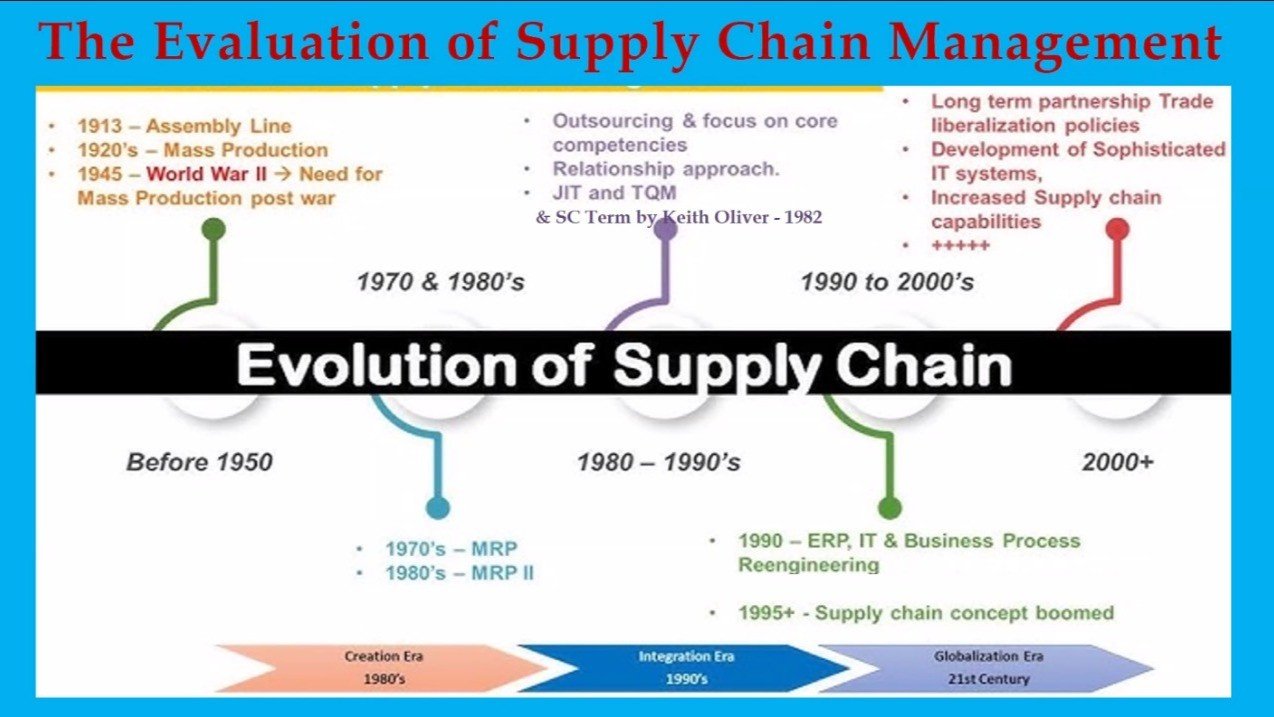

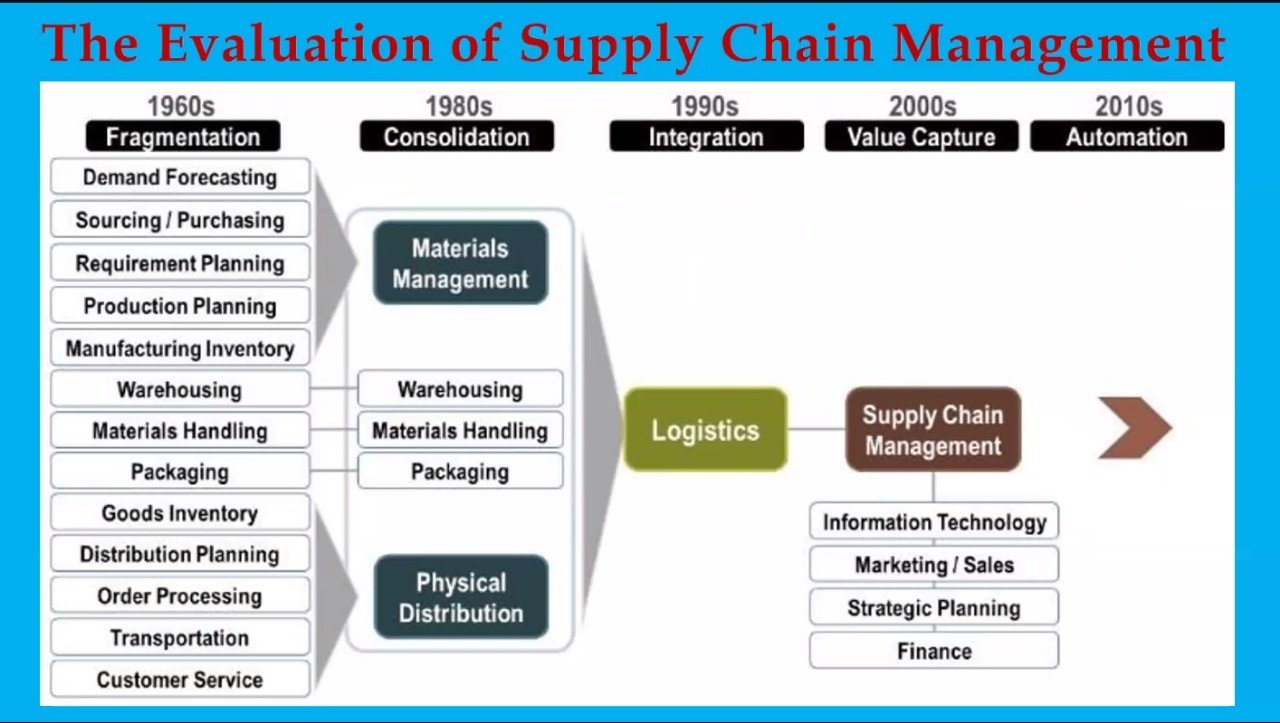

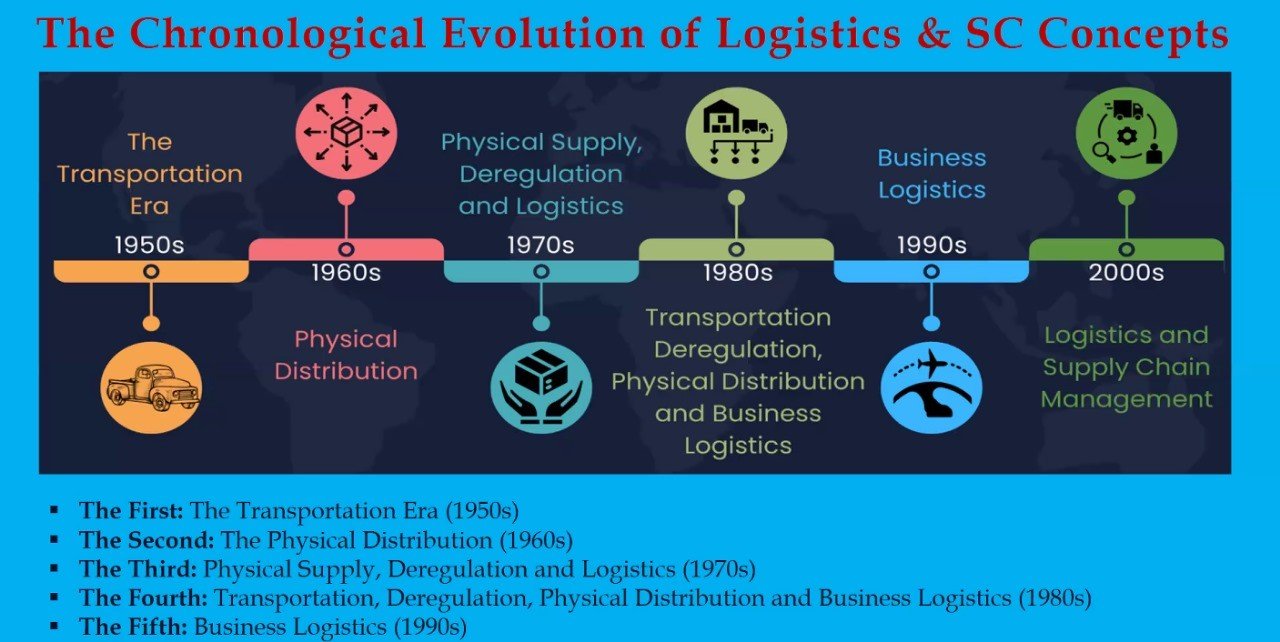

Supply Chain Management (SCM) has undergone remarkable transformations since its inception. Its evolution mirrors the growth of industries, technological advancements, and global economic changes. In this article, we explore the key milestones in SCM’s journey, break down its strategic significance, and delve into pivotal concepts shaping its landscape today.

Historical Milestones in Supply Chain Management

Before 1950: The Early Foundations

- 1913 – Assembly Line: The advent of the assembly line revolutionized manufacturing by enabling efficient mass production.

- 1920 – Mass Production: Standardized processes and economies of scale became critical drivers of industrial growth.

- 1945 – World War II: The post-war era amplified the need for mass production and logistics coordination to rebuild economies.

1970s to 1980s: The Era of Planning Systems

- 1970s – Material Requirements Planning (MRP): The introduction of MRP systems allowed businesses to plan production and inventory effectively.

- 1980s – MRP II: Enhanced MRP II systems integrated manufacturing processes with broader business functions.

1980s to 1990s: Strategic Shifts and Efficiency Focus

- Outsourcing and Core Competencies: Organizations began focusing on their core strengths, leveraging outsourcing to enhance flexibility and reduce costs.

- Relationship Approach: Collaborative supplier relationships emerged as a key strategy for competitive advantage.

- Just-in-Time (JIT) and Total Quality Management (TQM): These methodologies emphasized lean production and quality improvements.

- 1982 – “Supply Chain” Term Coined: Keith Oliver introduced the term, emphasizing integrated supply chain thinking.

1990s to 2000s: The Technology Boom

- 1990 – ERP and IT Systems: Enterprise Resource Planning (ERP) systems streamlined operations, integrating supply chain activities with IT advancements.

- 1995+: The concept of the supply chain gained widespread adoption, driven by globalization and complex networks.

2000 to Present: Digital Transformation and Advanced Capabilities

- Long-term Partnerships: Trade liberalization policies fostered stronger global collaborations.

- Sophisticated IT Systems: Advanced technologies, including IoT, AI, and robotics, transformed supply chain operations.

- Increased Supply Chain Capabilities: Companies now aim for end-to-end visibility, agility, and resilience.

- IoT and Robotics: Real-time tracking and automation have become indispensable for modern supply chains.

Key Concepts in Supply Chain Management

Flows Involved in Supply Chains

SCM encompasses three primary flows:

- Material Flow: Movement of goods from suppliers to customers.

- Information Flow: Communication between stakeholders to coordinate activities.

- Financial Flow: Transactions and payment processes ensuring seamless operations.

Competitive Advantage and the 3C’s

The 3C’s—Customer, Company, and Competitors—highlight the need to:

- Understand customer needs.

- Optimize internal capabilities.

- Differentiate from competitors to maintain a strategic edge.

Big is Beautiful Theory (Mass Production)

This theory emphasizes the benefits of large-scale production:

- Economies of scale lower unit costs.

- Standardization ensures consistent quality and reliability.

Vertical Integration

Vertical integration involves controlling multiple stages of the supply chain, from raw materials to final distribution. This strategy:

- Reduces dependency on external suppliers.

- Enhances control over quality and costs.

Bullwhip Effect in Supply Chains

The bullwhip effect describes how small changes in customer demand amplify across the supply chain. Solutions include:

- Improving demand forecasting.

- Enhancing communication between stakeholders.

- Implementing agile supply chain practices.

Process View of a Supply Chain

Viewing the supply chain as a series of interconnected processes enables:

- Holistic optimization of workflows.

- Enhanced coordination among suppliers, manufacturers, and distributors.

80/20 Rule in Supply Chain

The Pareto Principle suggests that 80% of results often come from 20% of efforts. In SCM:

- Focus on key products or suppliers that drive the majority of revenue.

- Prioritize critical customers to maximize impact.

The Road Ahead

As we look to the future, SCM will continue to adapt to challenges and opportunities. Sustainability, artificial intelligence, and resilience will drive the next wave of innovations, ensuring supply chains remain the backbone of global commerce.

This journey through the evolution of SCM not only highlights its historical significance but also underscores its critical role in shaping competitive businesses. By understanding its past and embracing future advancements, organizations can build robust and adaptive supply chains for the modern era.

#SupplyChainManagement #LogisticsAndSupplyChain #SCMTrends #SupplyChainInnovation #DigitalTransformation #IoTInSupplyChain #RoboticsInSCM #ERPSystems #JITManufacturing #TQM #VerticalIntegration #BullwhipEffect #GlobalTrade #MassProduction #CompetitiveAdvantage #SupplyChainOptimization #BusinessProcessReengineering #FutureOfSupplyChain #SCMInsights #SupplyChainLeadership